Nice part!!

Potter has built some nice lookin mills there and those Whipples and intercoolers are a big as the base engine-WOW! ITS TOP HEAVY!

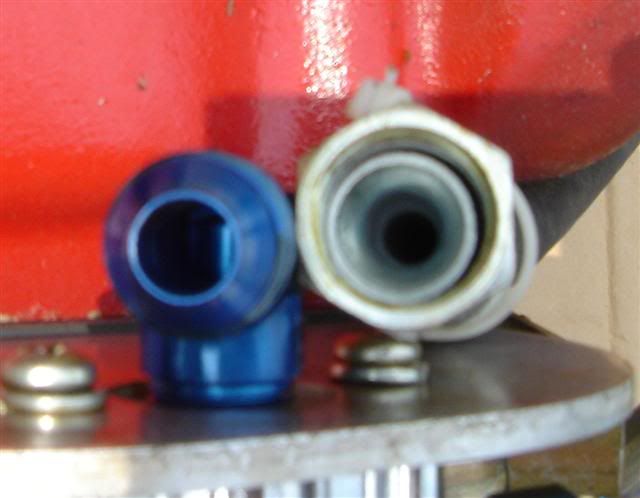

I am scratchin my head along with Eddie and others here why one would spend that much money and go wet sump, and try to get what appears to be one Aeromotive pump to supply the fuel needed for 1600HP. I've like others here have seen some of Sterlings 1600's and I never seen one with wet sump and that fuel system, but what the heck some people got the "answers" sure I don't , way outta my league! In any event I am sure there should be dyno work to prove the outputs. Good Luck Guys! Nice build and hope its everything everbody is looking for, not to mention F***ing Fast!!

Best Regards,

Ray @ Raylar

Potter has built some nice lookin mills there and those Whipples and intercoolers are a big as the base engine-WOW! ITS TOP HEAVY!

I am scratchin my head along with Eddie and others here why one would spend that much money and go wet sump, and try to get what appears to be one Aeromotive pump to supply the fuel needed for 1600HP. I've like others here have seen some of Sterlings 1600's and I never seen one with wet sump and that fuel system, but what the heck some people got the "answers" sure I don't , way outta my league! In any event I am sure there should be dyno work to prove the outputs. Good Luck Guys! Nice build and hope its everything everbody is looking for, not to mention F***ing Fast!!

Best Regards,

Ray @ Raylar